Volkswagen Group China has delivered the China Electronic Architecture (CEA) on schedule, paving the way for the successful rollout of its first CEA-based model, the VW ID. UNYX 07. Developed, tested and produced entirely in China, the VW ID. UNYX 07 has been developed for the next generation of intelligent connected vehicles (ICV).

Volkswagen Group’s China Electronic Architecture (CEA) marks the company’s entry into full-cycle software-defined vehicle production in China. This year, four additional CEA-based models will be launched across Volkswagen joint ventures. Developed by Volkswagen Group China Technology Company (VCTC), CARIAD China and Xpeng, the architecture supports end-to-end software-defined vehicle development from concept to mass production, with vehicles produced at the Volkswagen Anhui plant.

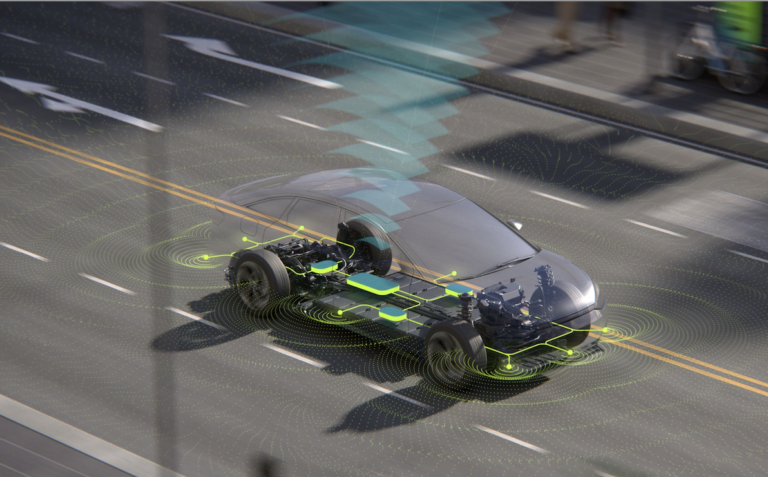

The architecture is a zonal electronic and electrical architecture with high-performance central computing. Designed as scalable and continuously upgradable, Volkswagen Group China is the first auto maker to deploy its zonal architecture across multiple vehicle platforms and all powertrain types – from full electric vehicles to hybrids and combustion engine cars.

Oliver Blume, CEO of Volkswagen Group, said, “The start of production of our first zonal electronic architecture marks another milestone in our ‘In China, for China’ Strategy. The Volkswagen Group delivered – quickly and reliably. In just 18 months, we have for the first time built a completely new, scalable electronic architecture from development all the way to series production – maintaining the high quality and safety standards that our customers expect from Volkswagen. The China Electronic Architecture enables software-driven innovations across all powertrain types, accelerates the expansion of our intelligent connected vehicle (ICV) portfolio in China – and represents a decisive step in our software strategy toward our ambition of becoming a global automotive tech driver.”

Significantly reduced development time and costs

Compared with previous generations, the CEA reduces electronic control units by around 30%, streamlining system complexity and providing a foundation for advanced AI cockpit functions, China-specific driver assistance systems and full-vehicle over-the-air updates.

The new development process shortens overall vehicle development cycles by up to 30% and, through localized development and early supplier integration, reduces development costs for selected projects by up to 50%. Agile processes also enable rapid adjustments to changing customer requirements, enhancing Volkswagen’s competitiveness in China’s intelligent connected vehicle market.

Ralf Brandstätter, member of the board of management of Volkswagen AG responsible for China, and chairman and CEO of Volkswagen Group China, added, “We have now blazed the trail for a new generation of intelligent connected vehicles in China. The China Electronic Architecture allows us to bring software-driven innovation to market at competitive cost and speed, across electric vehicles, hybrids and combustion engine models. This is how we scale intelligent connected vehicles in China – combining local speed with Volkswagen DNA.”

In related news, Volkswagen Group signs Qualcomm for the launch of its zonal SDV architecture