Staci Kono explains how Crystal Group can help with thermal management and other key challenges faced by those developing reliable autonomous transportation solutions, ahead of this year’s ADAS & Autonomous Vehicle Technology Summit North America, taking place on August 27 & 28, 2025, at the McEnery Convention Center in San Jose, California.

What is your company’s background?

Our strong partnership with industry-leading component manufacturers provided the platform for a joint effort to seed rugged hardware into the newly developing autonomous vehicle industry about a decade ago. The success and notoriety of that program aided in getting awareness of Crystal Group’s AI and autonomy solutions to a larger audience, enabling more collaboration opportunities in the industry. Given the tight-knit nature of this industry, we have had the opportunity to work with the majority of the autonomous vehicle leaders over the last several years. Crystal Group’s role continues to grow as the complexity of hardware requirements surrounding safety and reliability evolve.

What is your current role?

I’m the company’s senior program manager responsible for autonomous programs in commercial and defense applications. I work with our systems architects to gain a clear understanding of the unique needs and challenges this industry is facing, and then create targeted, custom designs to solve previously unsolved technological roadblocks. My primary goal is to eliminate the typical bottlenecks that pre-configured COTS (commercial off-the-shelf) hardware imposes on the end user. By working collaboratively with downstream engineering teams, we can support rapid, iterative design cycles to ensure leading-edge solutions are not only safe but also scalable.

What are some of Crystal Group’s key capabilities?

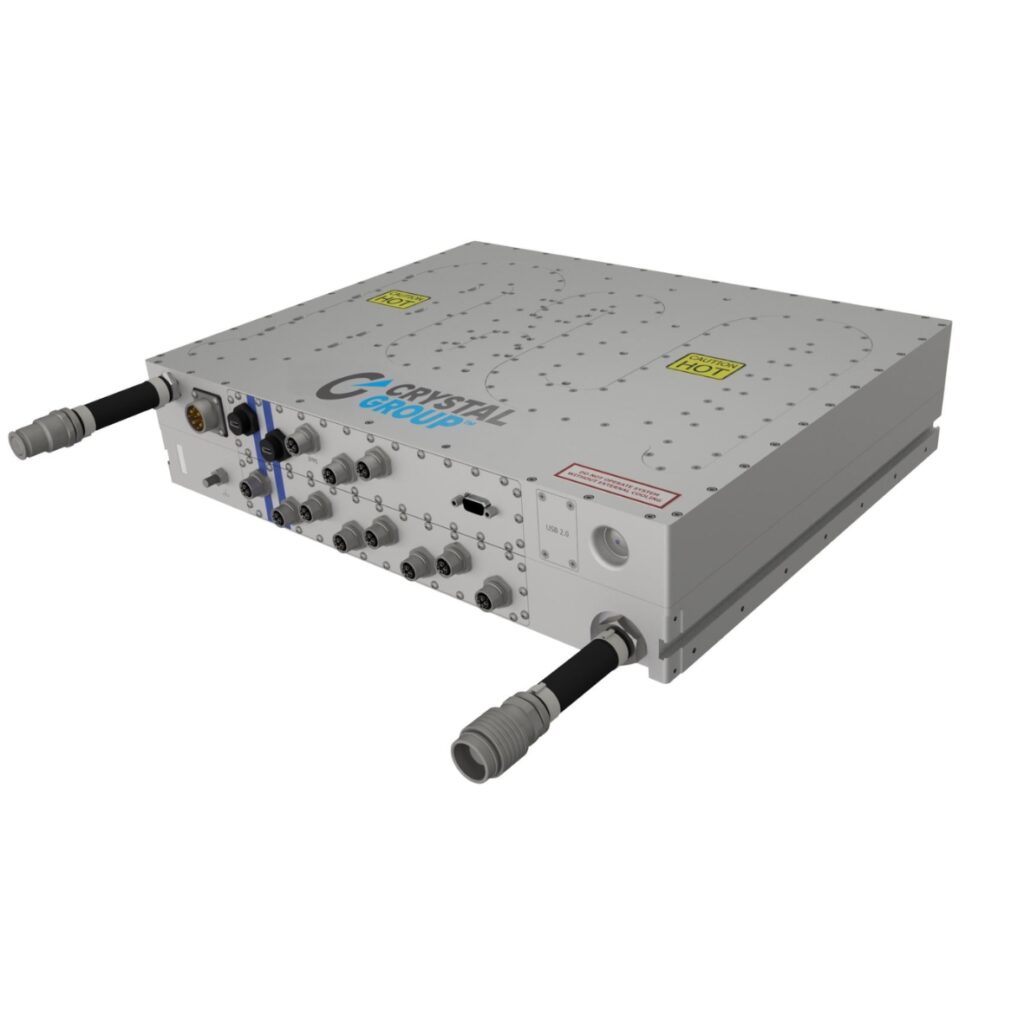

Crystal Group designs custom configurations and components to specific customer requirements and environmental challenges where traditional COTS hardware often fails. Crystal Group supports the commercial and defense industries, requiring our teams to keep their fingers on the pulse of cutting-edge technology needs and trends. The key differentiator for our customers is our custom power supply design, which was specifically developed to run directly off the vehicle’s alternator. This eliminates the need for a costly power distribution unit (PDU). Vertical design and manufacturing integration allow Crystal Group to support changing requirements and customer needs on short notice with maximum efficiency. Our 150,000ft2 [14,000m2] manufacturing facility supports custom component fabrication, COTS technology ruggedization processes and start-to-finish assembly and testing. Customers are often invited to participate in collaborative design sessions, enhancing seamless alignment between the technology solutions and program needs.

Where do you think you can help OEMs the most?

Our role in helping OEMs has been to provide high-reliability, production-grade, configurable autonomous vehicle compute solutions to AV integrators. By tailoring the solution to each use case using modular designs, we reduce cost while allowing flexibility with product roadmaps. By working with most autonomous vehicle integrators, our team has intimate knowledge of all the vehicle types being deployed, allowing us to quickly steer away from the known risks and challenges of the integration process due to that deep understanding of various approaches.

What next?

At Crystal Group, we’re committed to staying ahead of the curve, tracking fast-moving technology trends and adapting our rugged computing solutions to meet evolving mission demands. Our future-focused mindset, grounded in decades of real-world performance, allows us to anticipate industry shifts while drawing on deep experience to solve complex challenges before they impact the mission.

Our proactive approach is paired with a strong customer-first philosophy. From initial concept through deployment, we work side by side with our customers to develop custom solutions that meet their exact performance, size and environmental requirements. Whether it’s powering sensor fusion in autonomous trucks, enabling real-time AI inference for vehicle decision-making or ensuring reliable compute in harsh off-road environments, our team delivers the speed, quality and flexibility our partners rely on.

What are your plans for #AVTExpoCA?

We’re interested in collaborating with hardware and software engineering teams who are experiencing failures or challenges with their existing hardware due to lack of reliability. If you’re finding shortcomings with your existing COTS solutions, we’d be happy to discuss a custom design, integrating your specific hardware components. We will be displaying a plethora of our rugged technology and will have our team of subject matter experts on hand to collaborate in real time. These rugged systems already feature the latest-generation GPU technology and enhanced thermal performance. We look forward to this event every year as it gives autonomous vehicle leaders a forum to discuss the industry’s future and the technology roadmaps.

Meet the Crystal Group team at ADAS & Autonomous Vehicle Technology Summit North America in San Jose, California, at booth 4025. Register for your free exhibition entry pass here